FOCUS ON CUSTOMER NEEDS. INVESTMENT & PREVENTATIVE MAINTENANCE.

Universal Plastics prides itself on maintaining state-of-the-art equipment and facilities to meet your custom plastic manufacturing needs. Our 4 sites have a focus on preventative maintenance, a LEAN and continuous improvement culture, and are ISO 9001: 2015 registered.

Custom Thermoforming Facilities & Machinery:

- 260,000 sq ft of manufacturing space (3 factories)

- 2 tool rooms: Haas Mold Maker machining centers, Prototrack full 3 axis machining centers, all programmable via MasterCam for full 3-D machining capability; wood, metal working and a welding shop

- 3 quality departments: QC inspections with CMM machinery

- Class A automotive quality painting services, with state-of-the-art paint booths capable of handling part sizes up to 11’x11’x3’. We have 7 thermoforming paint booths, including 2 with high gloss cells

- 22 pressure formers (including 3 & 4-station rotary formers)

- 14 vacuum formers (including 3 2-station formers)

- 53 routing machines (including 5-axis trimming machines)

- Ability to form parts as large as 12’ x 9’

Injection Molding Facilities & Machinery:

- 150,000 sq ft of manufacturing space

- 17 machines ranging from 85-1,500 T

- Press sizes of 500, 700, 1,000 and 1,500 tons

- Quality inspection with 3D scanner & laser, a Cordax RS-150 measuring machine, colorimetric spectrophotometer, and gloss meter, among other measuring instruments suited for large plastic parts

- Part sizes from 70” x 80”

- In house painting, shielding and finishing – 9 paint booths, including nitrogen painting and automatic painting

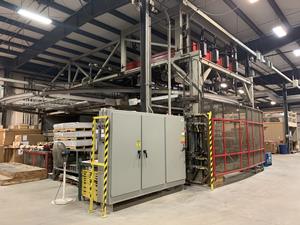

Blow Molding Facilities & Machinery:

- 120,000 sq ft of manufacturing space

- 16 extrusion blow molding machines ranging in size from 1.5 lbs to 30 lbs

- Multiple shuttle machines with continuous extrusion capabilities

- As a compliment to blow molding capabilities, also offer injection molding services with 2 machines in the 225 Ton range

- Part size capabilities range from 18 grams to 40 lbs

- Part dimensions as large as 36” wide to 66” long

Universal Plastics Capabilities:

Universal Plastics is a plastics processor specializing in custom thermoforming, injection molding and blow molding. Our expertise lies in manufacturing large, complex, highly aesthetic parts. To read about our 4 sites and capabilities, click here.