The Customer’s Challenge:

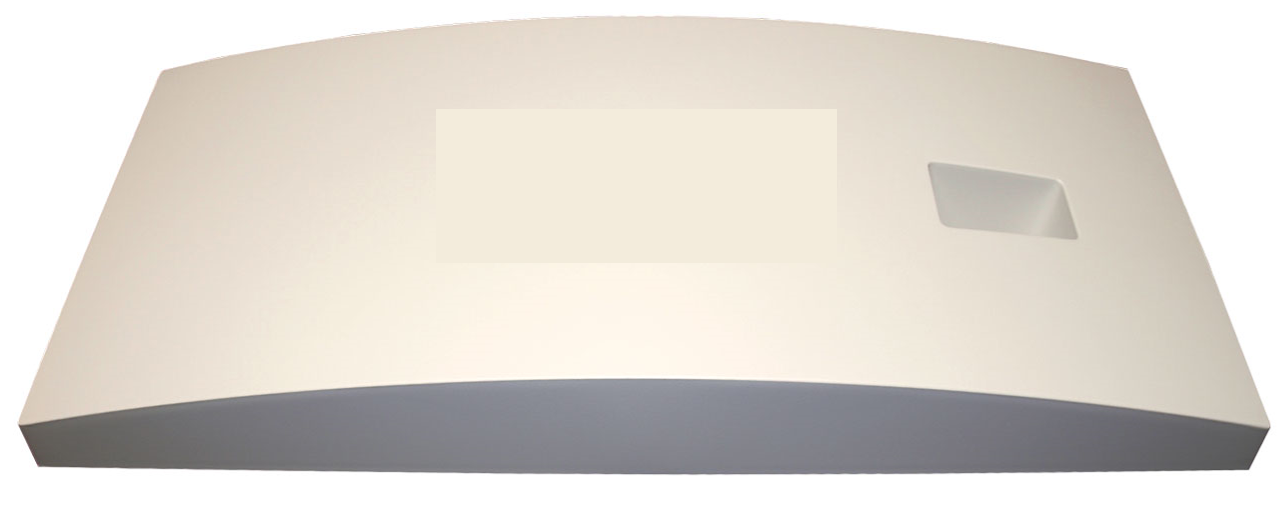

Contoured, clean lines were a must in this medical device application, with sturdy, non-warping face panel. Clean multi-color decoration was also a requirement. Critical requirements were:

- Highly contoured and cosmetically attractive covers for high end medical equipment

- Greater stiffness and structural rigidity

- Consistent coloration and finish

- Cost reduction; higher production capacity and repeatability

Universal Plastics’ Solution:

Universal Plastics produced a robust and smooth front panel, for easy cleaning with disinfectants. Brand integrity was maintained with a permanent, pad printed, decorative logo.

- Strengthening ribs added for stiffness

- Bosses molded in rather than added later with adhesive

- Elimination of warp; consistency of surface finish

- Attractive pad printing of logo on lower bezel housing

Why Injection Molding?

As a leader in gas assist injection molding for large parts. Universal Plastics provided:

- Superior surface finish; consistent textures

- High stiffness and structural stability with lower weight

- Elimination of warp

- Ease of cleaning